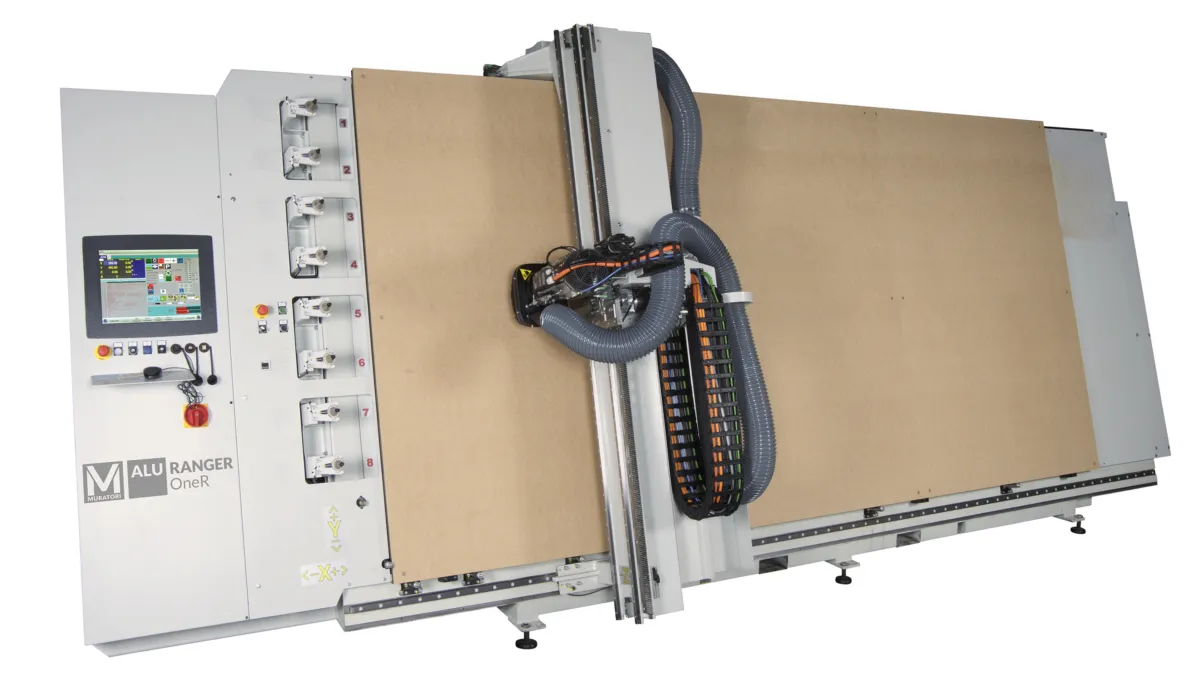

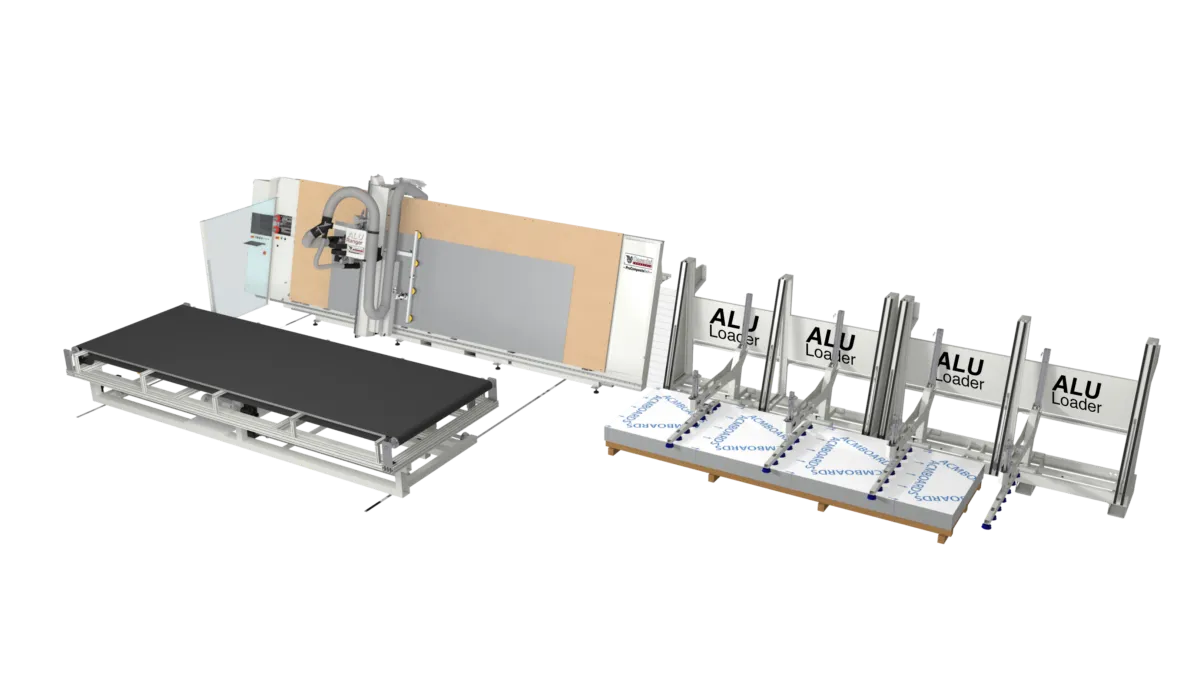

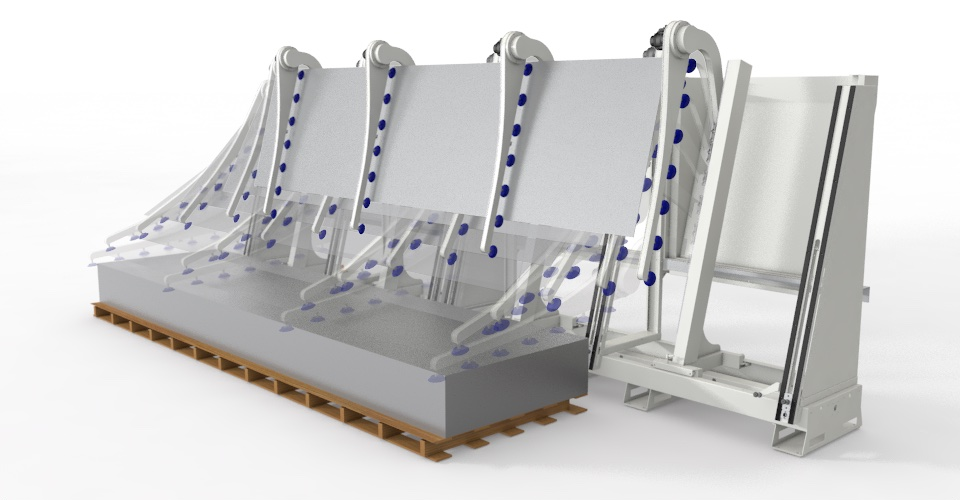

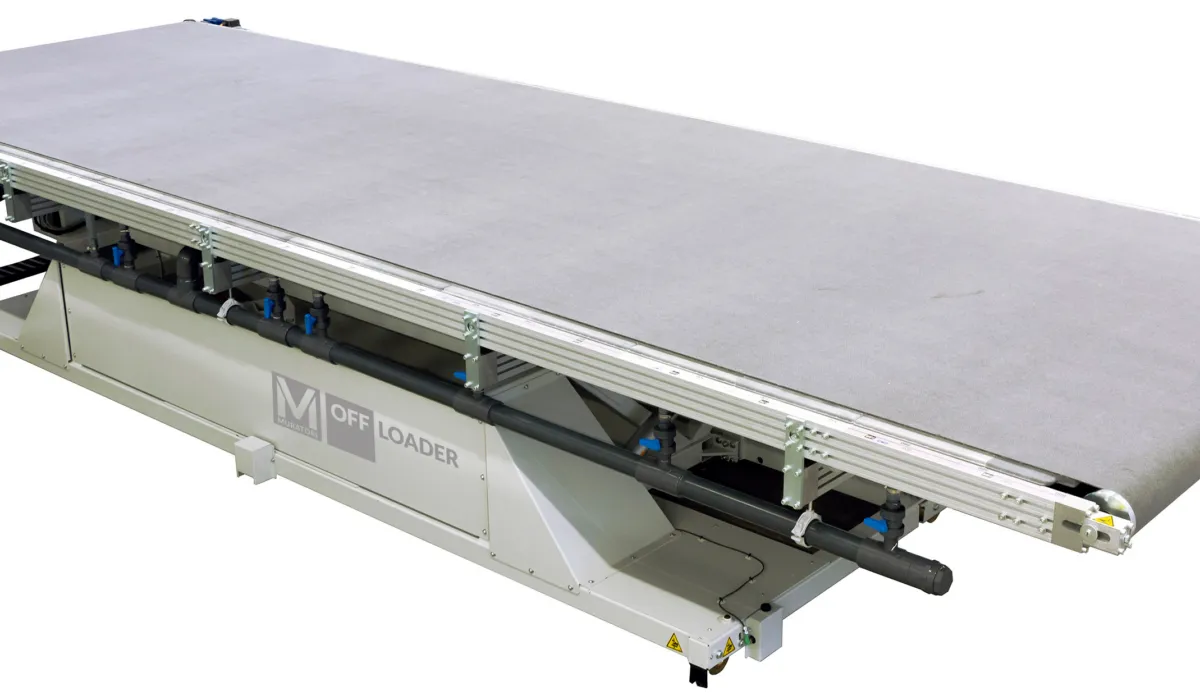

The high productivity of the Alu Ranger CNC, already guaranteed by the combination of the best tools, suitable for each different material, can be increased thanks to Alu Loader, the patented automatic panel loading and positioning system without an operator, and thanks to the possibility of also automatically controlling unloading, with Off Loader, the patented vacuum table covered by a breathable cloth. The integrated work cell-loading, processing, unloading-can be controlled and supervised by a single operator.